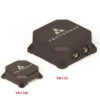

VectorNav VN-110

The VN-110 is a small, light weight, low power, high performance Inertial Measurement Unit (IMU) and Attitude and Heading Reference System (AHRS) available in a embedded module package for mounting to printed circuit boards or aluminum encased rugged module. The VN-110 incorporates the latest inertial sensor technology, combining 3-axis accelerometers, 3-axis gyroscopes and 3-axis magnetometers into a compact and rugged package.

Along with providing calibrated sensor measurements, the VN-110 also computes and outputs a real-time 3D orientation solution that is continuous over the complete 360 degrees of motion. It also features a robust Kalman Filter (EKF) along with a proprietary suite of high performance algorithms that run completely onboard the sensors. VectorNav’s industry leading Vector Processing Engine (VPE) algorithms provide real-time magnetic and acceleration disturbance rejection, adaptive signal filtering, dynamic filter tuning and on-board Hard & Soft Iron compensation.

Key Benefits

- Continuous attitude solution over the complete 360° range of operation

- VectorNav Processing Engine (VPE) for disturbance rejection, adaptive filtering, dynamic filter tuning

- Real-time gyro bias tracking and compensation

- Hard/Soft Iron Compensation (Real-time and Manual 2D & 3D)

- Inputs for external magnetometers or velocity measurements (Airspeed, GPS)

- Individually calibrated for bias, scale factor, misalignment, and temperature over full operating range (-40°C to +85 °C)

- IP 68 per IEC 60529 • Vibration & Shock (MIL-STD-810G)

- Temperature (DO-160G) • EMI & Radiation (MIL-STD-461G)

- Electrical (MIL-STD-1275E)

- Coning and sculling integrals (ΔV’s, Δθ’s)

- World Magnetic & Gravity Reference Models

- Data output format: ASCII (VectorNav), Binary (VectorNav)

- ITAR-Free

Ruggedized Packaging

The VN-110 features a precision milled, anodized aluminum enclosure designed to meet DO-160G standards. With dual I/O connectors the VN-110 offers maximum flexibility for interfacing with external GNSS receivers and IMUs. The VN-110 has an input voltage of +12 to +36 VDC power supply over a RS-422 interface.

- Size: 56 x 56 x 23 mm

- Power Consumption: < 2.5 watts

- Weight: 125 g

Enclosed in a precision anodized aluminum enclosure, the VN-110 offers additional protection of the internal MEMs sensors and electronics. The use of precision CNC milled aluminum parts ensures that the axis alignment provided by our factory calibration process is maintained during installation in its final configuration. Interfacing with the module is made through circular push-pull 10-pin connectors.

Tactical-Grade MEMS IMU

Utilizing the latest advancements in microelectromechanical systems (MEMS) technology, the VN-110 incorporates an suite of tactical-grade inertial sensors, including a 3-axis accelerometer, 3-axis gyroscope and 3-axis magnetometer. The VN-110 has been designed to achieve the highest performance possible by filtering out common error sources, such as sensitivity to supply voltage variations and temperature dependent hysteresis.

- < 1 °/hr in-run gyro stability

- < 10 µg in-run accel bias stability

- Ultra low noise accel and gyro (0.04 mg/√Hz and 3.24 °/hr / √Hz)

- High accel and gyro ranges (±15 g and ±490 °/s)

Extended Inertial Sensor Thermal Calibration

MEMS inertial sensors are subject to several common sources of error: bias, scale factor, misalignments, temperature dependencies, and gyro g-sensitivity. To ensure the highest level of accuracy, each VN-110 sensor undergoes a rigorous calibration process to minimize these error sources. Compensation parameters calculated during these calibrations are stored on each individual sensor and digitally applied to the real-time measurements. This calibration process is performed over the full thermal operating range of the VN-110 (-40°C to +85°C).